A sustainable and economical future

From 2015, the End of Life Vehicle (ELV) Directive, states that 95% of a vehicle by weight must be reused, recycled or recovered. The tougher limits, up from 85% previously, have forced automakers to look for more ways to reduce waste – one of these being the reusing of parts.

Thanks to advances in technology, OE-approved remanufacturers like Carwood can offer a product that performs like new again, extending its lifecycle several times over, whilst also significantly reducing the use of materials, energy, water and waste in the process – indeed it can save up to 70% of the resources and consume around 85% less energy, versus new.

But it’s not just the environment that benefits. With an increasing number of older vehicles on the road, the cost of replacement parts can be disproportionately high compared to the value of the vehicle. By reusing the core, remanufacturing also offers vehicle owners a highly cost-effective solution, without compromising on the quality of the part that is fitted.

With such concrete environmental and economic benefits, it’s easy to see why the UK remanufacturing market, according to the Society of Motor Manufacturer’s UK Automotive Sustainability report, is worth an estimated £2.4 billion. And is growing quickly.

Core to the Carwood business

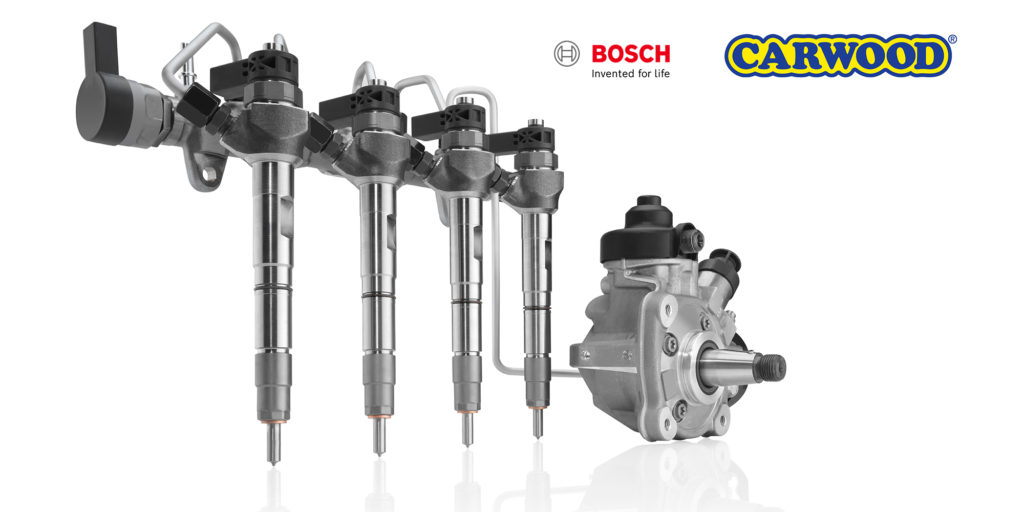

Although sustainability is more recent, remanufacturing has always been a core part of our business. Born in 1966 on the outskirts of Coventry, our reman journey began with starters and alternators. Back then, cost was the main driver, however, as these and environmental pressures have grown, so too has our portfolio. Today our remanufactured line-up includes diesel fuel injectors and pumps, diesel particulate filters, turbochargers, electronics, rotating electrics and engines for the automotive, agricultural, rail, marine, industrial and defence sectors. As well as new competition starters, alternators and batteries, HVAC components and a full range of specialist bus and coach parts.

Investing in the future

Whilst the logic behind remanufacturing may not have changed much over the years – returning a used product to a like-new condition – the processes, know-how and equipment needed to do it certainly have.

Take our Birmingham operation as an example. With sophisticated electronic products and software controls now common place, we have invested in a state-of-the-art diesel facility. Including over 20 OE test benches and an ISO14644, Class 7 certified clean room, capable of filtering down to 0.5 microns, it is widely regarded as one of, if not the best, diesel remanufacturing facility worldwide.

Likewise, our Nottingham plant is equipped with the very latest test rigs, so that we can check both the flow and actuator characteristics of today’s variable geometry turbos, and critically, reset to the manufacturers’ original specifications.

No matter where it is remanufactured, every Carwood part undergoes a rigorous, highly engineered, seven-step process including core inspection, product disassembly, cleaning, reinspection, replacement of parts with like-for-like OE, assembly and finally test and calibration. Only through this meticulous approach can we be sure to deliver a product that performs just like the OE, sometimes even better.

Together, this winning combination – quality, sustainability and price – means you can offer your customers a genuine alternative to new, that’s both better for the environment and their wallet. All with a great service. We call that a win-win.