Vixen wet blasting or dry blasting machinery?

As specialists in surface treatment machinery, we understand that different applications require different finishes. One finish could require dry blasting and the next could prefer wet blasting. So if you are unsure about which method would be better for your business, this article explains exactly that.

Everything You Need to Know About Dry Blasting

Dry blasting allows you to quickly and efficiently clean a wide range of components. From removing paints and surface coatings to preparing and finishing surfaces, dry blast cleaning is suitable for an assortment of industries.

Vixen’s Dry Blasting Machines

As Vixen is at the forefront of the industry, you can rely on us to provide you with a dry blasting cabinet that suits your needs. We’re proud to manufacture three different types of dry blast cleaning options, the Jetblast, the Jetair and one of our very first models, the Fox. All of the dry blast machines we provide are renowned for being affordable options that anyone can invest in.

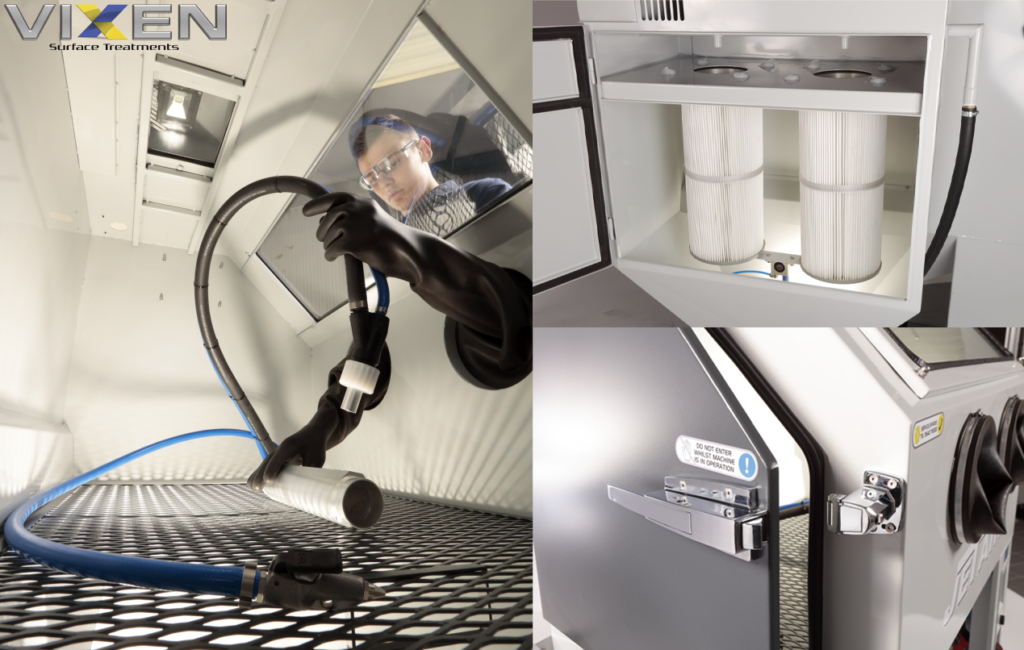

Jetair machines are top of the range and come in four standard sizes: VM30, VM36, VM42 and VM55. They come with a large window that allows you to see clearly into the machine itself while you operate it. Once more, boasting bright LED lights and a high-performance dust collection system, visibility is maximized during use.

We also provide an automatic, airless machine called the Jetblast. This free-standing machine has four revolving impeller blades that direct the abrasive media upwards at a high speed which then comes into contact with the component that is tumbling inside.

The budget-friendly Fox range consists of the 50, 25 and Bench Top 10 models. These compact and economical dry blast cabinets can be used in a vast array of industry sectors.

The Advantages

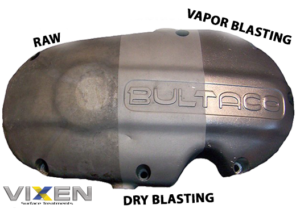

Dry blasting is an effective way of bringing certain components back to life. As there is no water involved with this process, it is ideally suited for materials that are unable to get wet. What’s more, it is highly abrasive which means it is able to remove stubborn paint, heavy rust and surface coatings with ease.

● Quick, clean and efficient results

● Cleans by the impact of the media

● Will not cause any metals to rust

The Process

There are two ways in which our Jetair’s can be used, there is the standard suction feed method and the pressure feed method.

The suction feed method is where compressed air is used to create a “venturi” effect which is used to suck blast media from the hopper of the cabinet and up to the blast gun where it is then propelled onto the surface of the components being treated. This helps to prepare metal components prior to any coatings such as paint or rubber.

However, with the pressure feed method, blast media is stored in a vessel that is pressurised when your foot touches the pedal. This then forces the media up to the blast gun. On the correct application, a pressure machine will typically clean 4 or 5 times faster than a suction machine.

Suitable Applications

Dry blasting is an ideal solution for components that require high speed, force and control blasting. This method is often used with popular abrasives such as glass bead or aluminium oxide and results in a good consistency finish. It can be used for:

● The removal of paint, rust, scale and carbon

● Surface preparation

● Deburring and peening

● Deflashing, cleaning and retexturing plastic moulds

● Etching, decorating and engraving glass

Everything You Need to Know About Wet Blasting

Wet blasting combines compressed air, abrasive media and water to achieve the desired finish on a chosen surface. Here at Vixen, we have expertly engineered vapor blasting technology that simultaneously blasts and degreases a vast selection of components.

Call Vixen today on 01642 769 333 to discuss