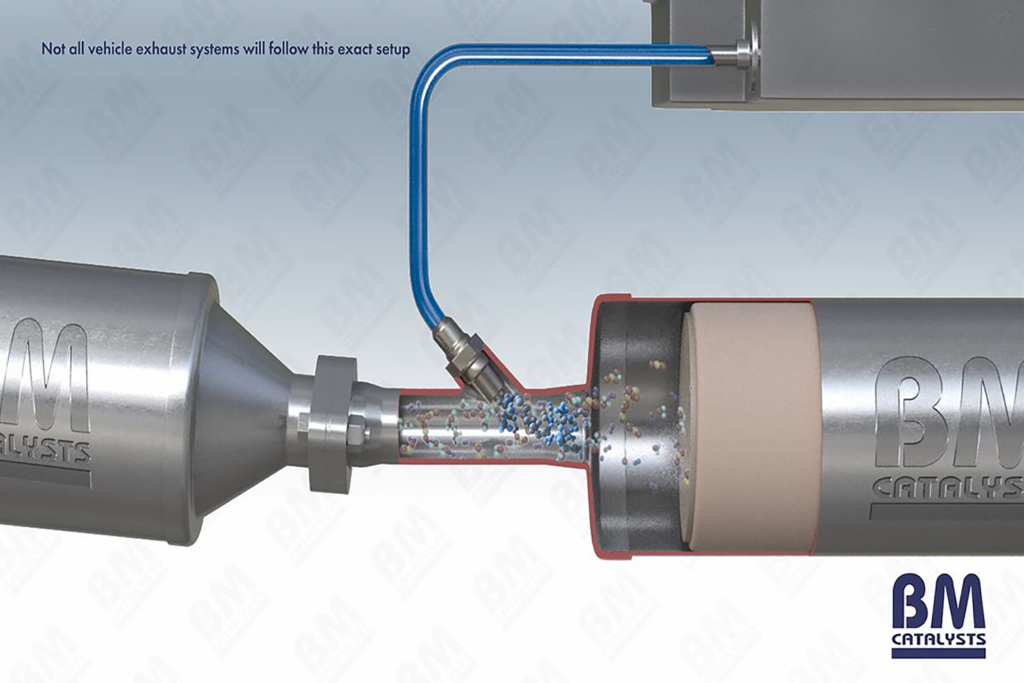

DPF regeneration requires extremely high temperatures, usually created under driving conditions, to remove build-up of soot via combustion. In traditional systems unburneddiesel is injected into the combustion chamber to provide the catalyst and raise temperature, however, research shows that this causes oil dilution, engine wear and increased frequency of servicing on vehicles.

Fuel Vapour Valves help to solve this problem. By directing fuel to the FVV prior to the DPF the system evaporates the fuel before it reaches the combustion chamber. The vapourised fuel can then be burnt on the catalytic converter to raise temperatures before the DPF, enabling optimal regeneration conditions removing the risk of oil dilution or requiring additional cooling. With the use of FVVs vehicles can regenerate more frequently under lower loads, or even at idle if needed.

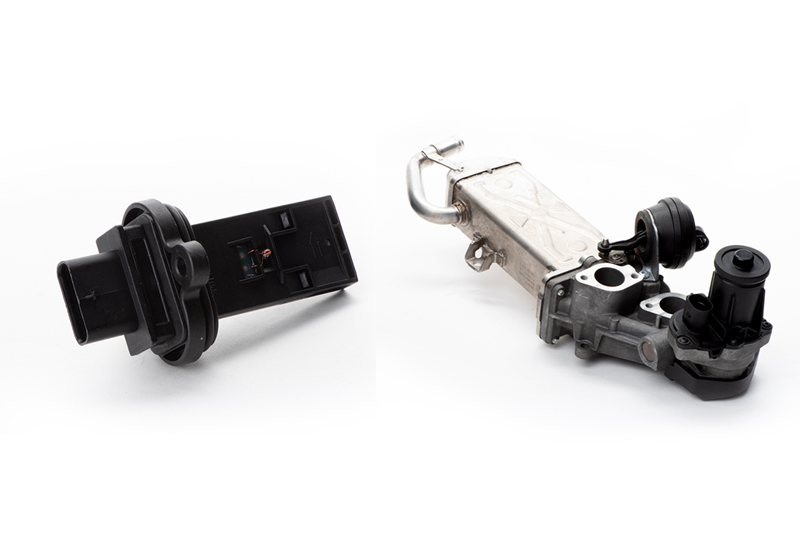

Fuel Vapour Valves are a common feature on Ford passenger vehicles. Whilst the technology is proven to improve engine life and performance, it is believe that 80% of Ford DPF problems are caused by failure of these components. As such, the demand for replacement parts in the aftermarket has grown and believed to continue to grow in coming years.

SMP Europe has a growing range of OE quality FVVs, with coverage for both Ford passenger and commercial vehicles, as well as Citroen and Peugeot vehicles that utilise ford systems.

sales@smpeurope.com

+44 (0) 1623 886400

SMP Europe, Unit 5b, Little Oak Drive, Sherwood Park, Annesley, Notts, NG15 0DR

www.smpeurope.com