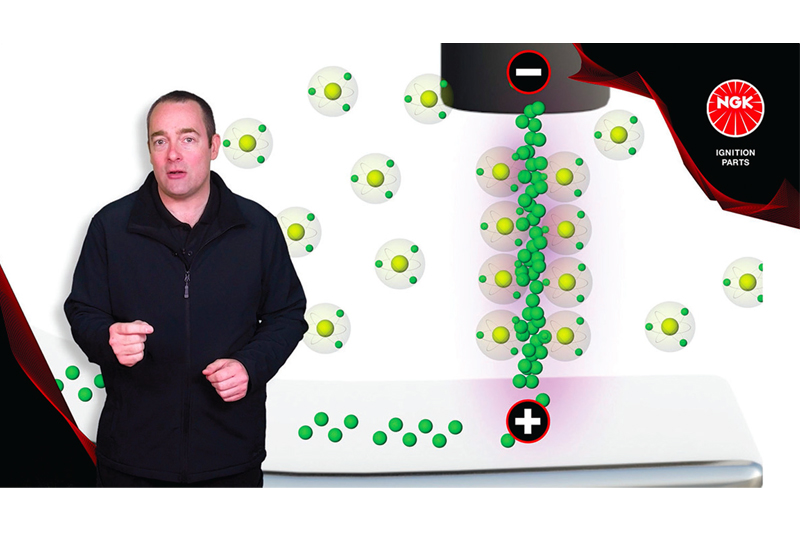

What is SiC?

SiC is a compound of silicon and carbide. Also known as carborundum, it is a material widely used in applications that require high thermal or strength endurance. It is mass produced as a powder which can be bonded together using heat to form a ceramic.

SiC has a wide variety of uses within several industries thanks to its low production cost and high thermal and strength endurance. Uses include sealants, car brakes, plates and clutches, furnaces, abrasive machinery, engineering and structural supports in nuclear power stations.

Why we use SiC in our Premium range

It has a melting point of 2,700°C so is extremely unlikely to melt during regeneration. It has to be made from small segments fixed together with special cement to enable it to cope with heat expansion. It also boasts 99% filtration efficiency and is commonly used in OE DPFs.

Properties of SiC

- High thermal conductivity

- Low thermal expansion

- Thermal shock resistant

- Semiconductor

- Corrosive resistant

- Does not melt at any known pressure

- One of the strongest known materials – second to diamond

Range

Our range of SiC DPFs is offered with a 3-year warranty against manufacturing defects. A significant number of our standard DPFs are available in the premium range, which is denoted by the “P” suffix.

The range covers a magnitude of vehicles including:

Alfa Romeo, Chrysler, Citroen, Fiat, Ford, Lancia, Mazda, Mercedes-Benz, Mini, Mitsubishi, Nissan, Peugeot, Renault, Saab, Seat, Suzuki, Vauxhall, VW, Volvo.

More information on the BM Catalysts product offering can be found here.