HOW A ROLLER BRAKE TESTER WORKS

Occasionally informally called a brake tester machine, a roller brake tester is part of the inspection lane for an MOT test. Unlike a plate brake tester, it allows checking of the braking system on a static vehicle. The roller brake tester is installed at floor height and features motor-powered driving rollers, operating at a low speed.

The majority of MOT brake testers are of the roller type. By contrast, very few plate brake testers are approved for use by the DVSA.

By operating the rollers on the tester and applying the tested vehicles brakes, mechanics can include a load to force traducers within the roller bed. These forces are used to measure individual axle braking forces per wheel, and allow the measurement and assessment of any braking imbalance between the vehicle’s left and right side. The brake tester also includes an integrated weighing system which allows overall braking efficiencies to be automatically calculated by the software.

In the United Kingdom, ATL brake testers are classed as legislative products. This means that the Driver and Vehicle Standards Agency (DVSA) defines how the equipment operates. As such, its status as an ATL brake tester means all models of roller brake tester must work in the same way. In turn, this allows for reliable test results across the country, regardless of the workshop or specific roller brake tester used.

PRACTICAL BENEFITS

Though it is a legislative product, workshop and MOT centre owners will still see multiple types of roller brake testers for sale. This includes Crypton’s high-specification ATL roller brake tester, which has been newly launched for 2021. While ATL roller brake testers do not differ in what they fundamentally do, there may be minor design changes depending on the equipment manufacturer. This can result in varying tester prices and performance.

Crypton’s tester is designed to be small enough to easily fit into existing civil work. Because it can be quickly installed, without the need for additional civil work, test lanes are kept out of action for comparatively less time. As a result, the financial impact of a non-working lane is reduced – a key concern for all workshops.

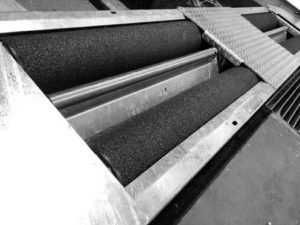

The MOT brake rollers included in the tester are also made of aluminium, so are three times lighter than traditional steel rollers. The reduction in weight makes maintenance easier, and the fact the rollers are made of aluminium means they do not oxidise.

Crypton’s new tester is designed with a high-grip, high-resistance epoxy coated rollers. This allows for maximum tyre protection and better simulation of a road surface’s coefficient, leading to more accurate testing results.

CHASSIS AND COVERS

Furthermore, Continental’s new tester features a galvanised steel frame and chassis, which houses the electric motor. This type of material has a longer lifespan and requires less maintenance.

The addition of hinged roller cover plates, instead of traditional, removable covers, also leads to a tidier workshop. As these covers are attached, they cannot be left lying around in the workshop during testing. They are also not at risk of being lost, as removable covers can be. Finally, the product is compatible with four-wheel drive vehicles, and a motorcycle brake tester can be included as an add-on.

CONNECTED BRAKE TESTER

Connecting equipment remains a major topic for garage owners and operators. Since the DVSA announced the launch of ‘Connected Equipment’ in October 2019, more parts of the test lane are expected to be connected to the MOT Testing Service (MTS).

Crypton’s new tester was therefore developed with connected MOT equipment in mind. Vehicle data can be inputted directly from the MTS to the brake tester programme, and data is automatically sent to the service without manual input required. Because of this, mechanics can save time, knowing testing information is being reliably, quickly and accurately provided.

Crypton’s new high-specification roller brake tester is available in class 4 (RBT240) and class 7 (RBT270).

For more information on this model, click here.

You can enquire using the contact details below or click here.

Tel: 0121 725 1400

Email: sales@cryptontechnology.com