External Factors can have an extreme impact on the lifespan of a wheel bearing. These include but are not limited to:

- Driving Conditions – driving through deep water or mud can cause the wheel bearing seal to fail. Water, mud and other impurities (such as dust or road salt) can sometimes get past the seals and enter the bearing, contaminating the grease and inducing wear in the bearings.

- Impact Damage or Poor Road Quality – all impacts from driving through potholes, over speed bumps or hitting curbs can damage a wheel bearing and reduce its service life.

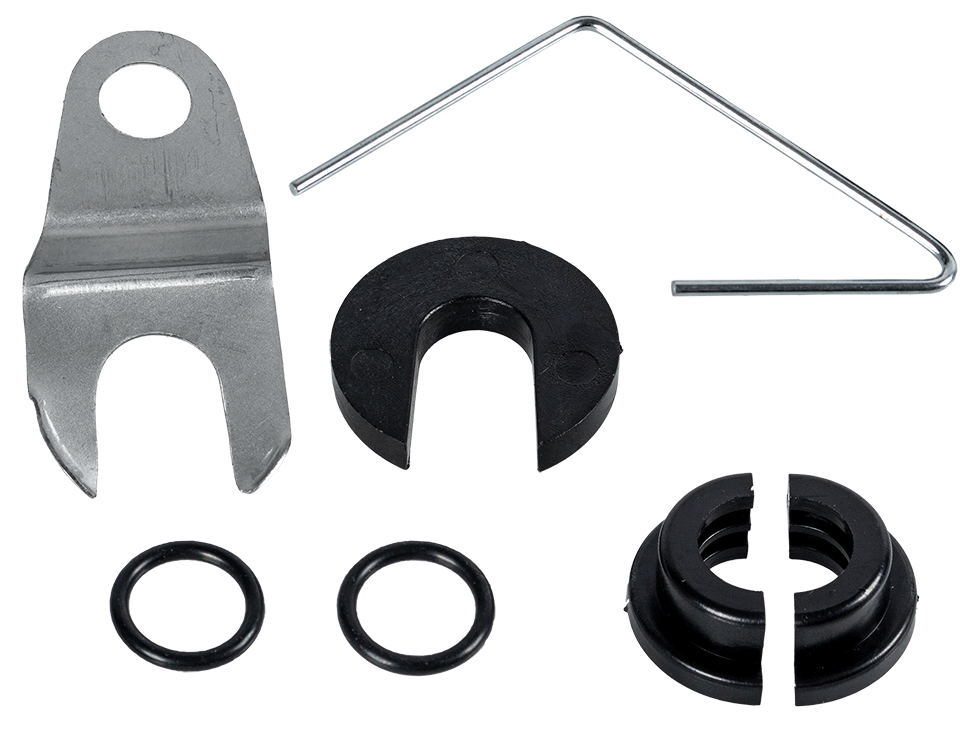

- Incorrect Installation – inappropriate tools, such as a hammer or an impact wrench, can cause damage to the exterior and/or interior of the wheel bearing, causing the bearing to fail prematurely. Also, reusing old accessories (such as bolts, nuts, circlips, split pins and seals) instead of replacing them with new ones can cause the wheel bearing to operate under abnormal or unsafe conditions, increasing wear. febi offers a range of technical bulletins to assist with any installation tips.

- Car Modifications – fitting larger or wider wheels, tyres with a lower profile, stiffer shock absorbers or suspension springs can cause higher loads on the wheel bearing and can accelerate wear.

Faulty Wheel Bearings have some recognisable symptoms, however a selection are often overlooked. For example:

- Noise from the bearing

- Steering wheel vibration

- Heat from around the wheel

- ABS indicator Light constantly on

- Uneven tyre wear

When replacing faulty Wheel Bearings it is essential only high-quality components are used. febi provide a range of more than 625 Wheel Bearing Kits in OE-matching quality.

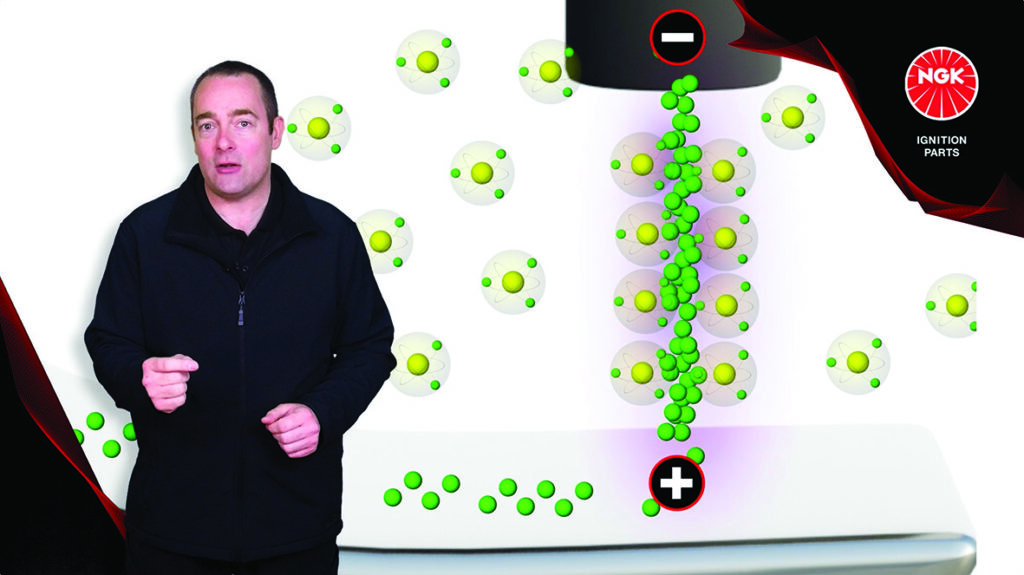

Testing, Testing, Testing

As with any safety-critical component, material checking and functional testing are of the utmost importance. This key process is not any different for the components that make up a wheel hub assembly. All materials used in febi wheel bearings, hubs and wheel fastenings are checked for hardness, strength and mechanical properties, and accuracy of size and functionality.

Lubrication and seals are also critical for the endurance of any wheel bearing. A wheel bearing is run under a salt and mud spray test for numerous hours to evaluate these components for durability.

Rotational testing: wheel bearings are examined for abnormal sounds, cracks, damage and any other abnormalities after reaching a test stage of over three times their typical product lifespan.

You can find our full range of wheel bearing kits at: partsfinder.bilsteingroup.com

Your No.1 for Wheel Bearing Kits

3-Year Guarantee

febi exclusively offers its customers’ replacement parts in OE matching quality. As a specialist with manufacturing competence, we only offer products with a high degree of installation safety and durability.

To underline our high product quality standards, we are providing a 3-year manufacturer guarantee for all of our replacement parts – exceeding the statutory warranty.