The new parts meet or exceed vehicle manufacturer (VM) standards and will give workshops an important new revenue stream with a range that covers more than 75 percent of the UK parc at launch.

Forty-part numbers covering 1200 application lines are featured in the new offering to give workshops the ability to deliver maximum customer satisfaction as their fitment will help improve vehicle performance and economy while reducing emissions.

Their introduction is the latest in a series of launches by Niterra UK Ltd and builds on the growing emissions management solution following the successful addition of NTK Exhaust Gas Recirculation (EGR) valves last year.

Becca Knight, Marketing Manager, Niterra UK Ltd, said:

“As a leading vehicle electronics specialist, we are always looking to enhance our offering with exactly what workshops need, and there has never been more focus on getting emissions management right.

“Exhaust pressure sensors are becoming more and more common in newer vehicles of all makes and are expected to experience positive market growth in the coming years; all aimed at helping reduce vehicle emissions.

“The NTK range covers petrol and diesel models from many of the world’s leading manufacturers. Exhaust pressure sensors are currently more prevalent in diesel vehicles, but their presence in the petrol market is set to experience a stronger growth rate in the coming years.

“The NTK range can cater for millions of vehicles on the UK and Ireland’s roads to help enable workshops to grow their business when they carry out repairs to their customers’ vehicles.”

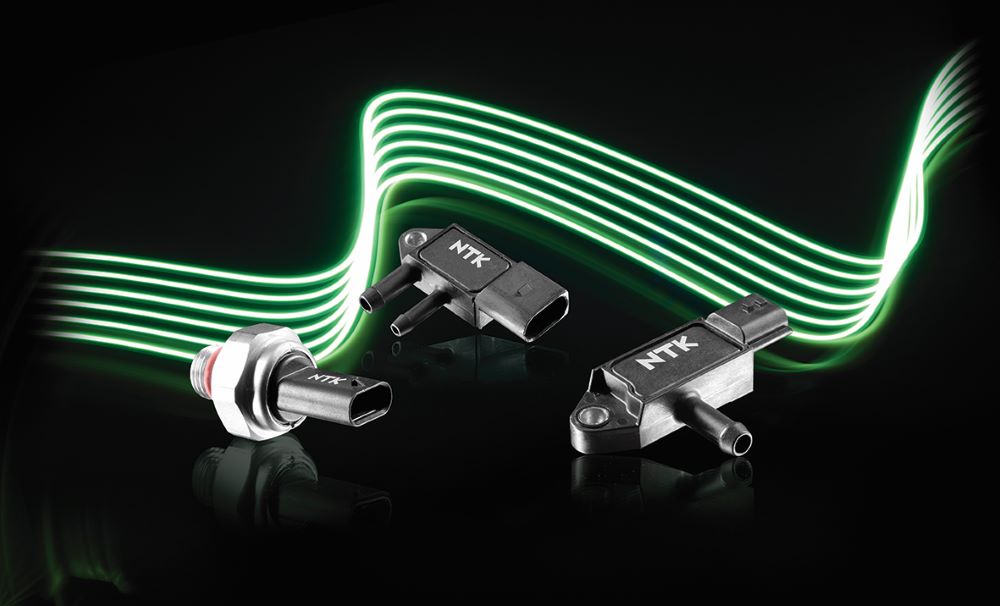

The new NTK Exhaust Pressure Sensors range comprises Differential, Absolute and High-pressure sensors and covers most of the world’s leading manufacturers and popular models including some BMW 3 Series, Ford Focus and Vauxhall Astra variants.

The sensors play a significant role in engine optimisation providing the engine control units (ECU) with the necessary information regarding the exhaust gas pressures and the filling level of the diesel particle filter (DPF) or petrol (gasoline) particulate filter (PPF/GPF).

Differential Pressure Sensors are connected before and after components such as the diesel particulate filter, the petrol particulate filter or the exhaust gas recirculation valve. Changes in pressure here can signal that the unit being monitored is not working optimally.

Absolute Pressure Sensors provide an absolute pressure measurement of exhaust gases. These monitor the pressure and warn should the back pressure become too high.

High Pressure Sensors are specialist sensors that do the same as the Absolute Pressure Sensors, only for gases with higher pressure.

The exhaust pressure sensors join the NTK family that includes lambda, NOx, MAF/MAP, camshaft and crankshaft and EGT sensors and EGR valves.