On its launch in 2013, the 1.4-litre TSI (CHPA) powered mark III Octavia, was the largest petrol engine in the Octavia range, a unit Auto Express magazine claimed at the time was ‘arguably the best engine in the line-up, as it combines impressive pace with good economy’. The powerplant is used across several VAG models, so is likely to be familiar to workshops throughout the country.

As replacing the timing belt requires the removal of the auxiliary belt, Dayco recommends that in addition to replacing all the primary system’s components, technicians check, and if necessary, change the auxiliary components at the same time.

This step-by-step technical guide will help technicians through the process, avoiding complications and ensuring a first-rate outcome. As with all primary drive system jobs, always check the timing marks before removing the timing belt and ensure the work is undertaken when the engine is cold, so ideally, the vehicle will not have been run for at least four hours.

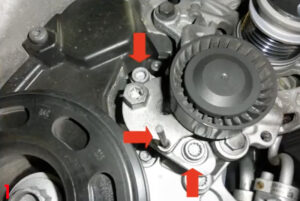

Start by removing the plastic guard from underneath the engine and then, after taking off the front offside wheel, the lower part of the plastic cowling from inside the wheel arch. This will reveal the auxiliary belt system and by relaxing the tension on the belt with a spanner on the tensioner, the belt can be removed. Before disconnecting the tensioner, lock it by inserting a pin as shown (Fig.1/main image).

Remove the cap in the engine block used to close the hole in which the crankshaft timing tool will be inserted and then disconnect the air intake to the filter box, take out the filter box and detach the pipes between the throttle and turbo, and the filter box and turbo, as well as the oil vapour recirculation pipe and the turbo air intake connector.

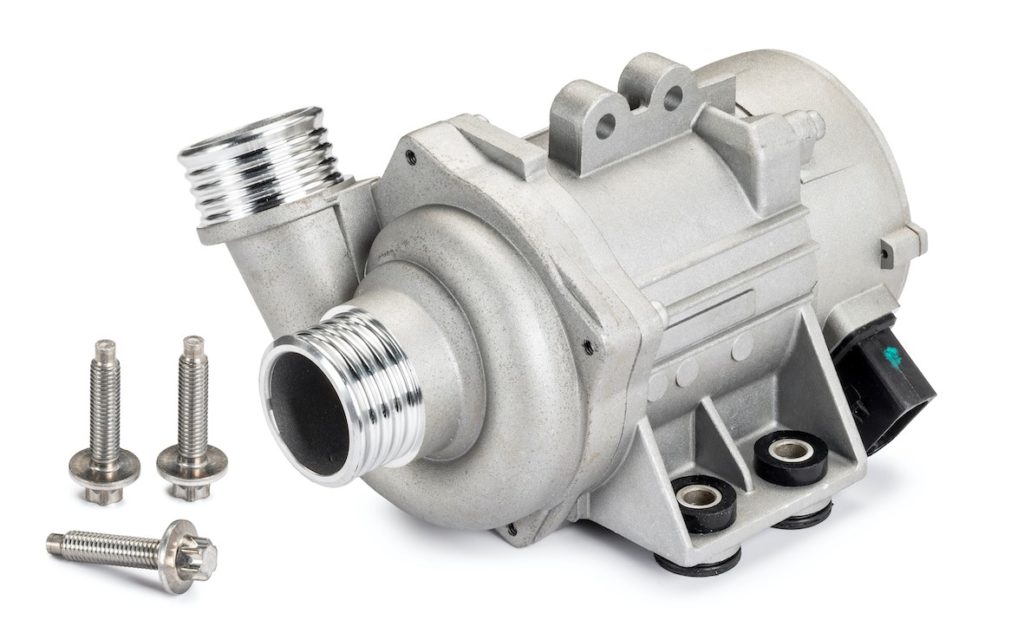

Now remove the water pump belt cover and the cover on the gearbox side of the intake camshaft, drain the cooling system and take off the upper cover of the water pump and the expansion tank, as the pump and belt should be changed at the same time.

Detach the upper timing belt cover, which will expose the variable exhaust valve timing unit on the left and intake on the right, and rotate the central crankshaft pulley screw clockwise and position the intake camshaft as viewed from the gearbox side as shown (Fig.2).

After disconnecting the ignition coil and removing the spark plugs, insert a screwdriver, which is long enough to touch the top of the number one piston at BDC and rotate the crankshaft to its TDC (the screwdriver will rise by 35mm).

Insert, and fully screw into place, the crankshaft timing tool (T10340) and rotate the crankshaft until the shaft rests on the tool. Then fit the camshaft tool (T10494) and after making sure it is in the correct position, lock it with a screw.

Using special tool (T102475), remove the crankshaft pulley, followed by the lower timing belt cover and the two alternator retaining screws to detach it. Then take off the plate shown (Fig.3), support the engine appropriately from above and remove the top engine mount adjacent to the timing belt and take off the central timing belt cover to access the tensioner and idler. After removing the cover of the left (exhaust) and the central cap of the right (intake) variable valve timing units, take off the tensioner and timing belt. Appropriately lock the valve timing units, remove the centre screws and the units themselves.

Attach the new idler, Dayco ATB2637 and torque to 45Nm, and tensioner, Dayco ATB2636, ensuring it is fitted as shown (Fig.4), and then fit the valve timing units on the corresponding camshafts, but do not fully tighten their screws.

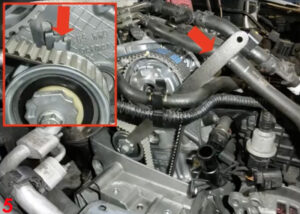

Fit the new timing belt, Dayco 941060, installing it clockwise from the crankshaft pulley via the tensioner, exhaust and then intake camshaft pulleys and the idler. Use the special tool (T10499) to move the needle of the tensioner to the right, about 10mm beyond the fixed reference and then back to the middle of the fixed reference as shown (Fig.5), finally tighten the tensioner fixing screw to 25Nm.

Suitably lock the valve timing units and tighten their screws to 50Nm before removing the camshaft timing tools and temporarily refitting the crankshaft pulley to enable the engine to be turned through a few clockwise revolutions.

Tightening up

Check the belt tensioner needle remains in the right position, and using the crankshaft and camshaft tools, the timing is still correct. If so, appropriately lock the valve timing units and tighten their screws another 135°.

Now remove the water pump with the belt drive and after flushing out the cooling system to remove any debris and cleaning the water pump facing, reposition the replacement pump, with the new belt, Dayco 941094, at the same time.

It is extremely important to follow the correct tightening procedure when reattaching the water pump cover, so first tighten the screws to 10Nm in the sequence shown (Fig.6) and then loosen by one turn.

Put a hex screw in ‘A’, torque to 30Nm and hold the torque wrench in position while retightening screws 2, 1 and 5 to 10Nm and then 3, 4, 5, 1 and 2 to 12Nm.

Refit the components in reverse order of their removal, tension the crankshaft pulley screw to 150Nm + 180° and the crankshaft timing tool cap to 30Nm. To follow best practice, Dayco also recommends the replacement of the auxiliary tensioner Dayco APV3270 and the auxiliary belt Dayco 6PK1000.

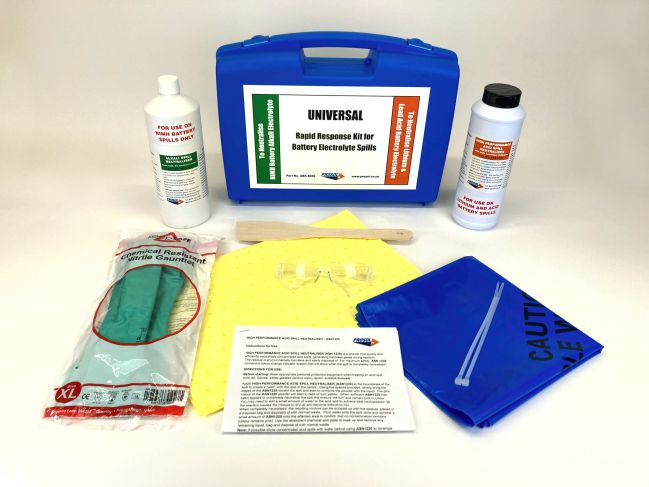

Finally, refill the cooling system, start the engine and carefully check for leaks and ensure the radiator fan is operating correctly. Then, once the engine is cold, check the level of the fluid again.