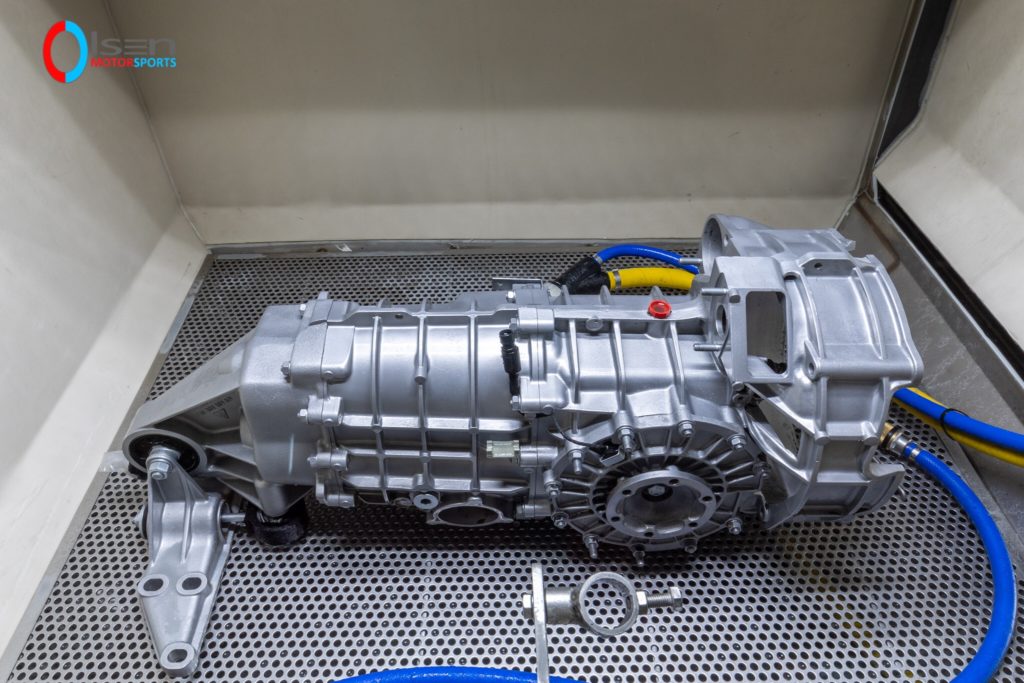

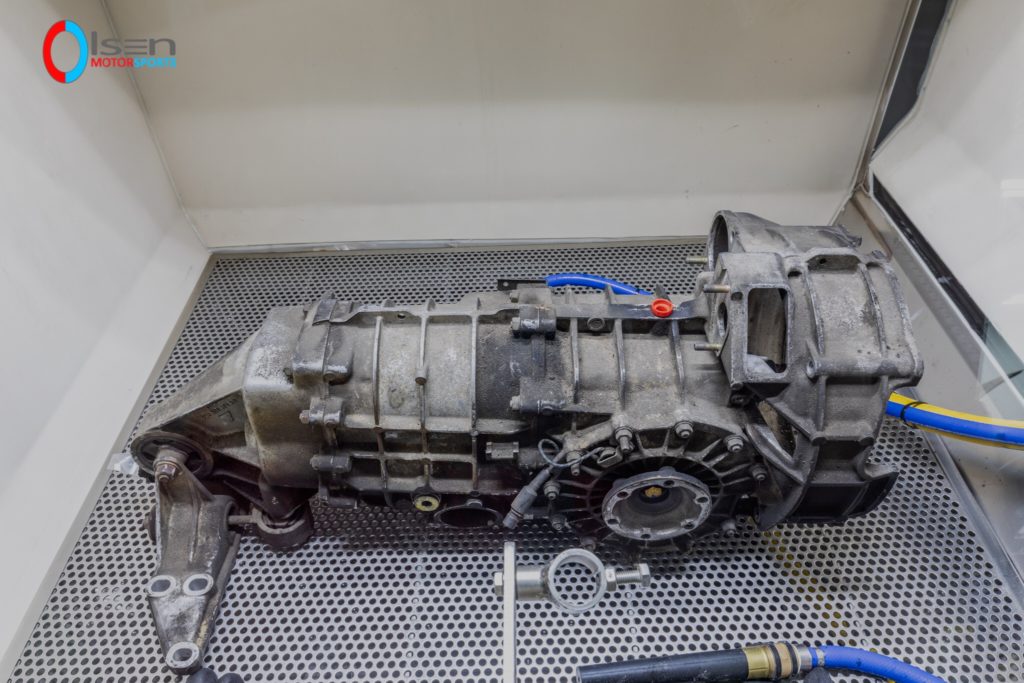

Olsen purchased an Aquablast 1215 to restore vehicle parts in their workshop. The Vixen wet blasting machine enables the parts they process, to pass inspections and create a consistent factory finish every time.

John from Olsen Motorsport visited one of Vixen’s distributors located in the USA, where he was able to test the equipment before he decided to purchase one for himself. John said: “Rick has been very generous, both with testing time and assistance from the start.”

John then went on to say:

“The Vixen machine has impressed existing and potential clients so much so that we have received additional and new work! It is the workhorse of our operation. This vapor blaster is how we make things look beautiful, shiny and lustre. It uses water, media and air and is fully self-contained. Parts look like they’ve just come straight from the factory!”

The Aquablast 1215 is the second largest of our standard wet blasting models, which is suitable for medium to large sized components.

This cabinet cleans by flow, thereby eliminating impact, resulting in a ‘soft’ finish with the water acting as a lubricant. Media impregnation is avoided and the life of the blast media is also extended. View the full process below:

- The water/media slurry is contained within the wet blasting cabinet sump.

- Delivery of the slurry to the manual blast nozzle is via a glandless polyurethane pump and associated hoses located inside the wet blasting machine.

- Compressed air is added at the blast nozzle to accelerate the slurry and provide the cleaning effect.

- After contact with the component the slurry, then drains back into the sump creating a re-circulating system.

- Fine broken down media and other contaminants are fed via an overflow to a sedimentation filter located at the rear of the wet blasting machine.

For further details on our full range of wet blasting cabinets and how you can transform your bodyshop.