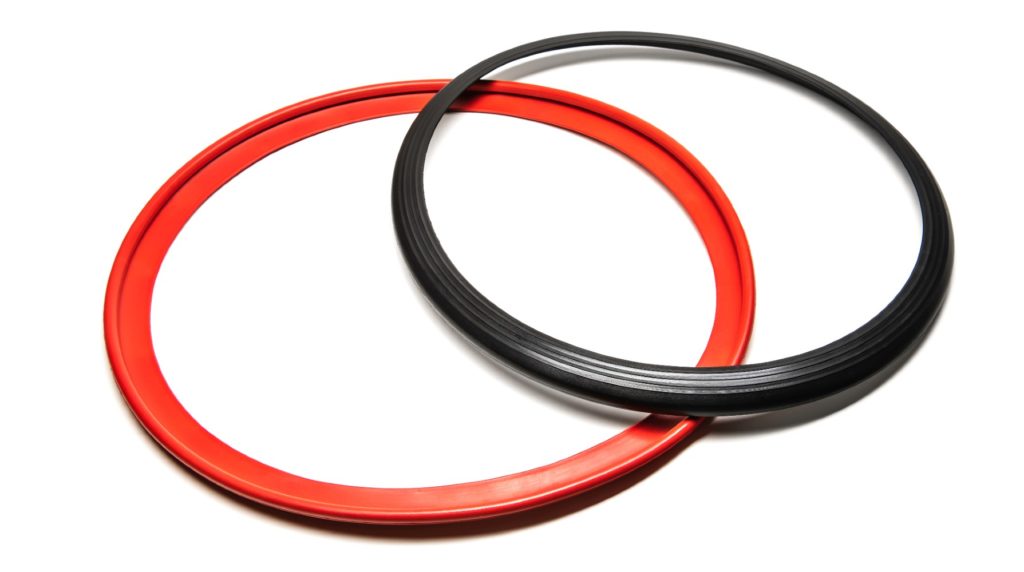

Continuous Band Technology

Zero join means 100% integrity of the protector – no chance of dislodging, no chance of detachment damage. Unlike jointed technology which means an inherent weak spot that could potentially cause air leakage and sudden deflation. This could result in safety issues and detachment damage as the loose end rotates at high velocity against bodywork.

Does Not Foul The Rim Face

(Sits proud of rim) – meaning Rimfinity does not trap abrasive road salt, grit and brake dust between the wheel rim protector and the face of the wheel. Compare this to traditional tyre-trap protectors that do cover the rim face – allowing road salt, grit and brake dust to become trapped and effectively ‘sand down’ the soft alloy surface as the protector moves under acceleration and braking.

A Wheel Size Specific Product

This ensures you get a perfect fit and function for your exact wheel size. Traditional alternatives are universal, meaning the product must be cut to size, and the join hidden with a separate glued on plastic ‘join cover’

100% Natural Rubber

Absorbs and deflects a range of impacts from flying stones and track debris, to brushes with roadside verges and even full on kerbing. Hard nylon (plastic) alternatives are less likely to absorb impact without deforming leaving this type of protector looking very worn and tatty after impacts.

Robust Rubbing Area

The most robust rubbing area of any product in existence. Protects both alloy wheel AND tyre sidewall due to unique profile design. Little or no tyre protection is offered by most traditional tyre-trap protectors.

Fast Fit

Professional ‘fast-fit’ in just 3 minutes per wheel – no cutting tools or adhesives required. Depending on product, traditional tyre-trap protectors can take three times longer to fit due to the additional steps required in cutting and jointing.

Ribbed Natural Rubber

Ribbed 100% natural rubber tail section (where protector ‘traps’ between tyre and wheel) – no hard nylon, no ‘teeth’ to damage the wheel or tyre. Traditional nylon tyre-trap protectors typically utilise hard plastic ‘teeth’ which are designed to dig into the soft inner surface of your alloy wheel on reinflation of the tyre.

ISO 9001:2015

Manufactured to ISO 9001:2015 quality standards. Designed from the outset to meet or exceed stringent OE (Original Equipment) standards. On the other hand, traditional tyre-trap products have varying quality standards depending on brand and manufacturer.

Design and Manufactured in The UK

Design and manufactured in the UK by Rimfinity for total control of production and quality standards. With the alternatives, manufacturing varies by brand and manufacturer, often production is outsourced meaning little control nor guarantee of consistent quality.

Suitable For The Road or Off Road

Rimfinity has been developed to suit fast road and off road applications. The technology works with both modern and classic alloy wheels, and steel wheels (as found on Pick Up trucks and utility SUV’s for example). Rimfinity has also been approved for use on radial, cross ply and run flat tyres.

If you have any questions, please contact