The valves are equivalent to their original equipment (OE) counterparts and phase one of the launch will occur with the introduction of 45 references.

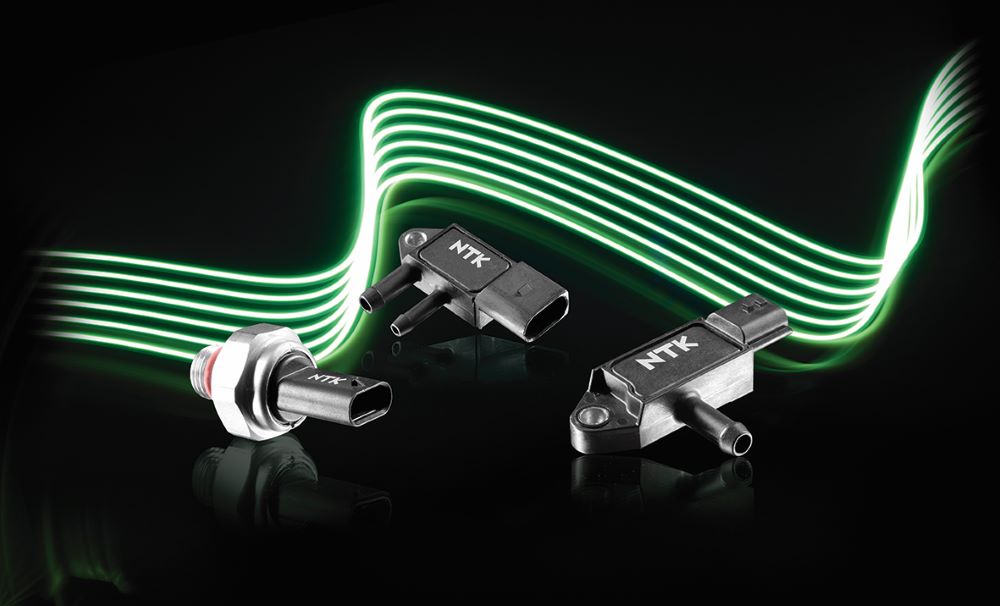

The move follows a number of successful recent NTK launches in the UK, including camshaft & crankshaft sensors and Mass Air Flow (MAF) and Manifold Absolute Pressure (MAP) sensors, and further strengthens the company’s aftermarket offering which currently provides customers with a one-stop shop for all their vehicle sensor needs.

The new range offers the same high quality that all the other NGK SPARK PLUG products are renowned for, supplying emission performance that is in accordance with ‘EC Euro’ norms. To ensure this, all references undergo, and pass testing carried out in extreme conditions.

This includes thermal shock testing in temperatures ranging from -40°C to 150°C, tests on valve, cavity and cooling leakage, as well as electrical resistance and lifecycle. OE-style accessories such as gaskets and/or O-rings are also included in the box. In addition, smart and well-protected packaging will allow for easy identification, stock management, inspection and scanning, as well as safety.

Peter Hayden, General Manager – Sales & Marketing, NGK Spark Plugs (UK) Ltd, said: “With the upcoming launches of our EGR valve ranges, we will yet again improve on the comprehensive coverage and convenience that we provide to our aftermarket customers.

“An EGR valve range has been a market request for many years. This demand will now be fully satisfied, enabling our loyal customers to access all their vehicle electronics portfolio needs in one convenient place.”

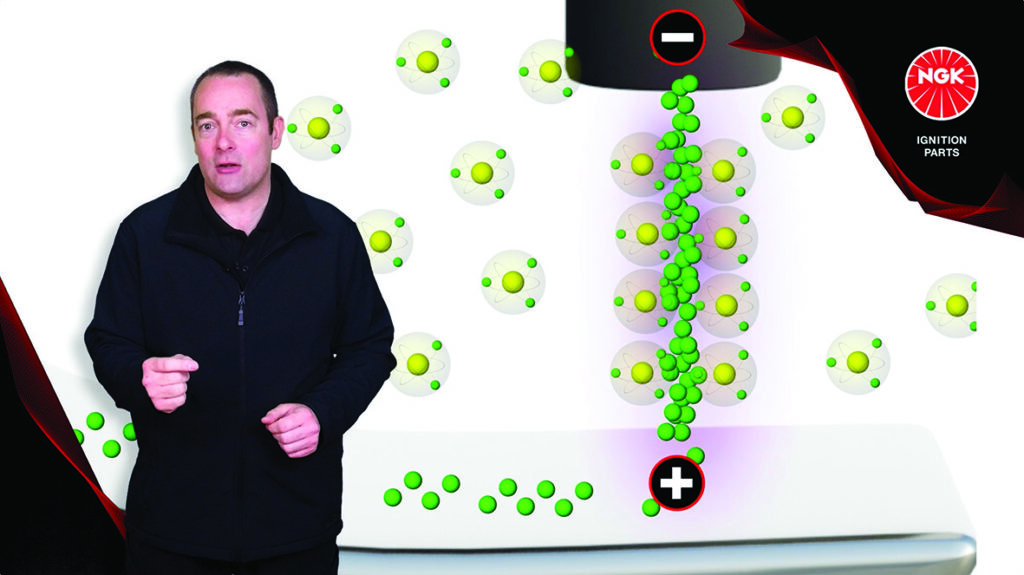

The principal function of the exhaust gas recirculation system (EGR) is to reduce the amount of harmful nitrogen oxides (NOx) that are produced during the combustion process. NOx is created when high combustion temperatures enable the nitrogen and oxygen present in the air-fuel mixture to combine. EGR valves come in three different types – ‘pneumatic’, ‘electric’ and ‘electric with cooler’ – and operate by taking some of the exhaust gases from the exhaust manifold and then reintroducing these gases into the intake manifold, mixing them with fresh air.

Originally developed at the beginning of the 1970s, EGR valves first started to be used in Europe in the 1990s in order to meet the ‘Euro 1’ emission standards. Today, 100 percent of diesel cars are equipped with EGR valves and 30% of petrol cars. Many new models will be even equipped with two EGR types (low pressure and high pressure), which means that the replacement part market for these types of valves is likely to grow, corresponding to the level of demand.

NGK SPARK PLUG will introduce its EGR valve range over several phases, along with a further phase which will focus on range optimisation.

NTK services for the new EGR range will be wide-ranging. These will include a local distribution presence and premium quality service. In terms of documentation, customers will be able to locate specific references on NGK SPARK PLUG’s ‘Part Finder’, ‘TecDoc’, MAM Autocat and ‘Catalogue’ (printed, PDF and excel). Customers will be able to access technical videos at www.ngkntk.com/uk – which will provide detailed insights into the workings and installation procedures of the EGR valve range.